Use Case Witzenmann – Streamlined process thanks to binding rules

In this Use Case, we show you how Witzenmann automates its process steps with a CPQ solution and considerably shortens the throughput time from quotation creating to order processing.

(PDF 510 KB)

Project goals

Witzenmann was using a configurator that had been developed in-house. However, this no longer fulfilled the increasingly complex requirements (including international application) and was also no longer adequate enough to handle company expansion. The company consequently decided to introduce future-proof software that could reliably manage the large number of product variations and also facilitate more efficient, continuous processes.

Results

All data is now automatically forwarded from one process phase to the next. As a result, the processing time needed to document customer requirements, create a quotation and process the order in manufacturing is considerably shorter. Binding rules enable reliable and accurate configuration and manufacture of the many variations.

About Witzenmann

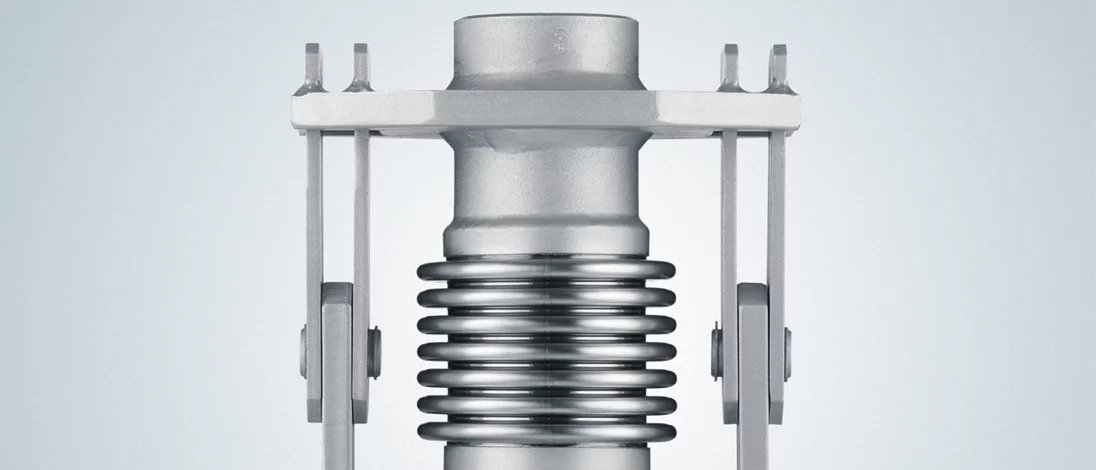

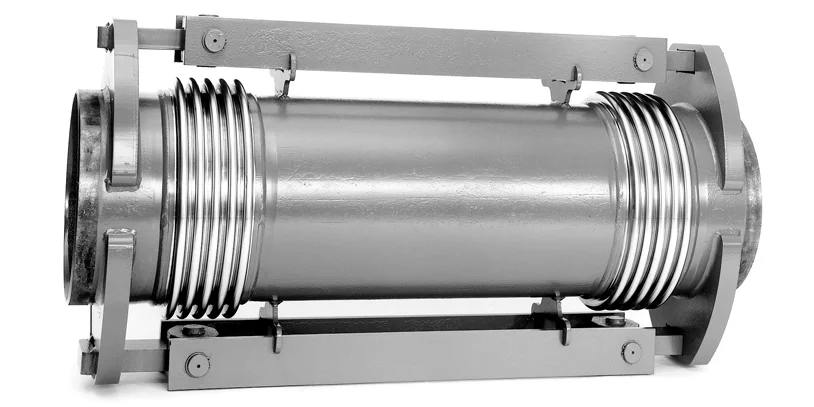

Witzenmann has a successful track record that is typical of a German SME. In 1885, jewellery manufacturer Heinrich Witzenmann from Pforzheim invented the flexible metal hose together with Eugène Levavasseur; four years later they started manufacturing on an industrial scale. The company has grown steadily ever since. In 2014 the group generated sales of around EUR 520 million with its 24 subsidiaries and 3,700 plus employees worldwide. The range of products has also been continuously expanded since the company was first established. Today Witzenmann products – hoses, bellows and expansion joints – can be found in a range of different environments: in households they connect gas cookers and tapware; in vehicles they channel oil, fuel and coolant safely to their proper places; on account of their durability they are installed in aircraft and spacecraft; and they are also used extensively in various industrial petro-chemical facilities.

‚When it comes to industrial facilities, the requirements are extremely specific, particularly for expansion joints,‘ explained Joachim Fleig, who heads IT Engineering Applications at Witzenmann. Expansion joints are flexible metal components that absorb movements in pipeline and conduit systems. One example is a pipeline in Siberia, where the extreme differences in temperature cause the pipes to expand and contract considerably. Without elastic expansion joints between the rigid parts, cracks and leaks would quickly form. Because expansion joints need to be specifically configured for the various applications, Witzenmann does not manufacture products in bulk for the industrial sector, but rather on an individual basis or at most in small batches. In doing so, to maintain competitive rates and delivery times, the company has for years strived to achieve broad variant diversity through product modularisation.

The requirements

For a long time, Witzenmann organised its diverse product range solely using a manual that listed 3,500 different types of expansion joint according to nominal diameter and pressure stage. In the late 1990s, the first modular system appeared based on Excel. The system comprised standardised parts that could be combined to produce a specific expansion joint. This succeeded in reducing the number of different components by 80 per cent and enabled manufacturing to operate much more efficiently. However, many product variations were nonetheless requested that were not covered by the limited modular system. Consequently a method had to be found that was as comprehensively standardised as possible, yet could also achieve broad diversity. The company approach was to use specific parameters to infinitely vary initially established sizes for individual parts. Expanded in this way, the solution space created enables millions of variations to be offered.

To map this technically, in 2003 the Industry department developed its own configurator, which was constantly expanded in the following years through the dedicated commitment of all the parties involved. ‚Internally a great deal of know-how was built up in the process that formed the basis for all the other phases,‘ said Hans Bimmüller, who supervised the project from the outset. Within the course of international expansion at Witzenmann, it became progressively clear that introduction of the configurator within the globally dispersed subsidiaries could only be achieved with great difficulty.

Selecting the solution

Joachim Fleig: ‚For this reason we wanted to replace the configurator we had developed with a future-proof solution from an established provider. The fact that this would have to be an extremely powerful solution was clear from the very outset as a combination of product and manufacturing processes would need to be mapped.‘ Essentially there were two core aspects. Firstly, from initial contact between sales and the customer right through to manufacture of the ordered expansion joints, the entire process chain had to be mapped so that manual intervention was no longer required. The configurator effectively had to forward all the data to SAP in such a way that the data could be used to process the order. Secondly, solution roll out had to be easy and quick. In selecting a software that could tick all these boxes, those responsible at Witzenmann had their eyes on camos at a very early stage. Not least because one of the company‘s own customers had recounted their own positive experiences with the Stuttgart-based software and consulting company. ‚We looked at the solution in practice and were pretty impressed with the reference project. At the end of talks between camos and ourselves, we had established that it would be an extremely ambitious project that could be successfully brought to fruition with camos Develop,‘ said Joachim Fleig.

Inside the project with camos

The plan was for the new configurator to go live at head office and the first branches two-and-a-half years later. However, the first phase of the project revealed that to create a continuous, streamlined process chain, individual company processes first needed to be adapted. That resulted in corrections being made to the respective IT systems that had not been considered prior to the project start. Another challenge was coordinating the various interests of the departments involved – sales, technology, order preparation, welding engineering, manufacturing, central departments, calculations, materials engineering and IT „From a technical perspective, optimal implementation of the many interfaces within the configurator and to external solutions was a particularly complex procedure. In the case of a bellows, for example, upwards of 70 different attributes had to be forwarded to SAP with absolute reliability so that order processing, including work schedule, stock lists and drawings, could run automatically“ explained Hans Bimmüller. Nicole Geiger, responsible for the quotation process at Witzenmann elucidates: „Reconstruction of the interfaces from the camos software to SAP ERP gave us a unique opportunity to convert from customer-specific processes to SAP standards. The years of experience gained with our legacy configurator also flowed directly into this process.“

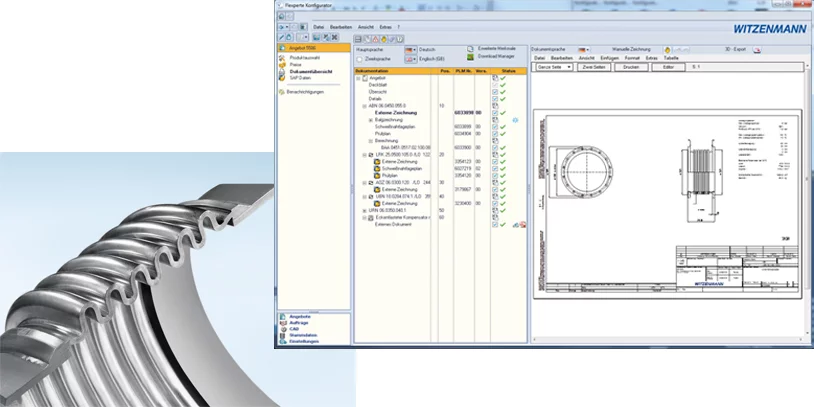

CPQ solution in use

The configurator – called ‚FlexKo‘ at Witzenmann – ultimately went live at the head office in Pforzheim and 14 subsidiaries on 1 June 2014. ‚In cooperation with camos and a number of freelancers, our interdisciplinary project team were responsible for the solution being very positively received by users in the various departments and all our expectations being met in full,‘ declared Joachim Fleig. Including, for example, the continuous process chain configurator SAP – PLM – CAD. All the data is automatically forwarded from one process phase to the next – effectively from requirement documentation by sales to quotation generation, including 3D models and 2D drawings, all the way through to processing of the order in manufacturing. Where a customer has individual specifications that are not covered by the defined solution space, then as was previously the case the project is dealt with as a custom design on a separate process path. The new procedure has quickly shown results at Witzenmann. Processing times have been perceptibly shortened and additional testing of products by the technical department is no longer required. Not only is manufacturing more efficient, but the delivery times are also shorter.

Joachim Fleig: ‚ In addition, the new solution makes it much easier to configure the correct variation. That is a massive advantage, above all in terms of our international expansion, because we are now also able to quickly bring in new employees that have not yet acquired comprehensive technical know-how‘. The configurator has already been rolled out at four more subsidiaries since the initial go live. Functional expansions are also planned for the next few years, which will also include an online version for customers. Also in the pipeline is the future integration of further engineering tasks within the configurator. Witzenmann ultimately want to successively expand the solution space to offer even more variations and consequently reduce the number of custom designs. Accordingly, the success story of the German SME is set to continue.