Using CPQ to achieve a holistic and customer-centric Industry 4.0

Industry 4.0 today: A lack of customer focus

Components, products, assembly robots and people are increasingly interlinked and communicate with each other across sites: The German industry is in the middle of its fourth industrial revolution - with the Internet as the central technology driver. According to the PWC study ‘Digital Factories 2020: Shaping the future of manufacturing’ 9 out of 10 industrial companies in Germany already invest in the digital factory. They pursuing three overarching goals: Efficiency and revenue increases and a stronger customer focus.

As far as digitisation, networking and automation in the production and logistics sector are concerned, the German industry is on the right track: Today, one in four machines is already smart and networked in factories. Productivity and flexibility in production especially benefit from these technical measures. Yet these things, alone, do not comprise a customer-centric Industry 4.0, yet: To achieve this, companies must also network with their customers in order to focus on their individual requirements. Only if you know the customer requirements and incorporate them into the production process can you exploit the full potential of flexible and efficient production.

Diversity of variants as a key challenge

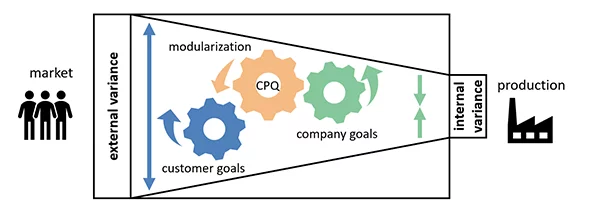

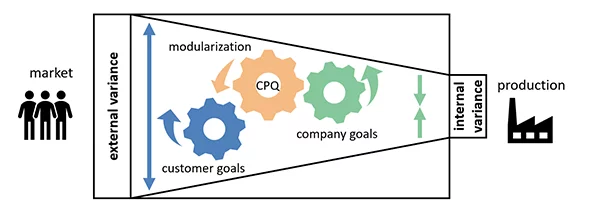

Customised production opens up new opportunities for value creation: If you manage to understand your customers’ requirements even better and meet their specific wishes in the optimal way, you open up new sources of revenue. At the moment, 78% of German industrial companies have already recognised that customer-centric individualisation of products is a strategically important issue for their company. However, merely 16 % are able to produce a size 1 batch at the cost of series production. The key challenge is that processes and products must be prepared for the necessary product variety. The variety of products offered on the market leads to an unmanageable complexity in production, inflates business processes and reduces economies of scale. Thus, the objective must be a low internal, technical variance on the production side. On the market side of things, on the other hand, the external, functional variety should be kept as large as necessary in order to meet all individual customer requirements. Only when combined can individualisation become the norm and the customers’ and company’s goals can be equally achieved: Customised products under conditions of series production. In practice, CPQ (Configure Price Quote) systems with modular construction kits make this possible.

Cost-effective individualisation with CPQ and modular construction kits

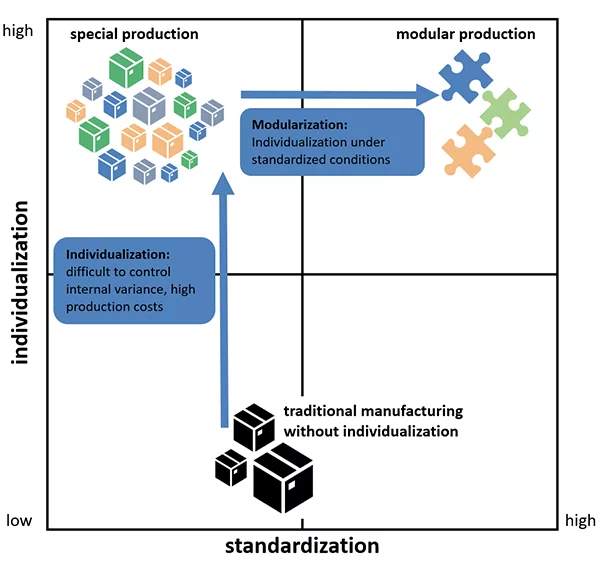

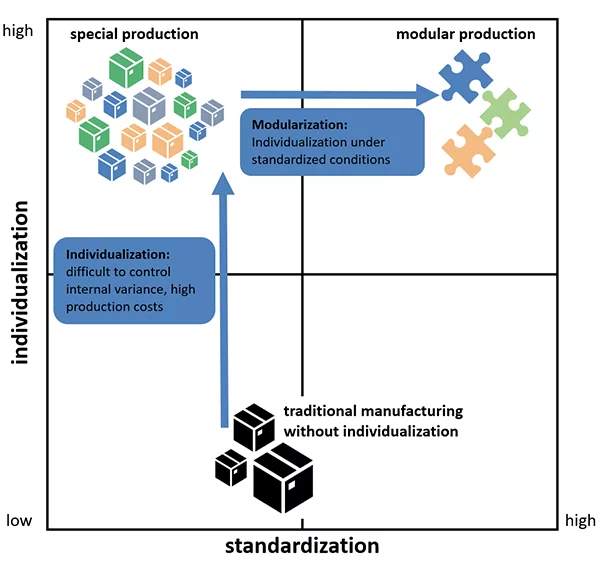

Individualisation thus also preconditions that marketing and engineering are incorporated both strategically and systematically: In which functions does the customer require variance? How can these functions be mapped in the product so that they can be produced quickly, cost-effectively and flexibly? Can synergetic effects from different areas of use with similar requirements be used? The result of these considerations is a concept for modularisation that divides complex products into standardised, functional modules.

CPQ systems take these modularisation concepts to sales - and to the customer. They enable the configuration of products via modular product building blocks and can map all configuration options based on predefined rules: The modules keep the internal variance within limits from the outset, and the set of rules ensures that the ‘buildability’ of the products is guaranteed. The numerous combination options of individual modules promise a high degree of external variance on the market. At the same time, the variety remains easy to control for the customer via a product configurator: He is guided based on his requirements through the variety of products and in the end arrives at the product that suits him best.

Within a holistic and customer-centred Industry 4.0 concept, the configurator at the interface to potential customers represents the starting point of the digital process chain. It already integrates them in the digital processes as early as the product selection and configuration phase, records their wishes in a digital form for the first time and transfers the requirements to the subsequent processes without system disruptions. Prices and offers with cover letter, calculations and drawings are automatically generated on the basis of the custom configuration with CPQ systems, and the offer data can be used seamlessly to make specifications. The orders are transferred to the ERP system, where parts lists and work plans are prepared, in order to then directly trigger production tailored to the customer requirements.

Reaching customer-centric Industry 4.0 goals with CPQ

By using CPQ systems, the goals of holistic Industry 4.0 projects can be achieved: They assist companies in becoming more efficient, focusing more on their customers’ needs and increasing their revenues. The software builds a digital bridge between interested parties, sales and production - with advantages on all three levels:

- The customer experiences a greater focus on their own requirements and acquires a clear idea of ‘their” product already in the offer phase: For example, through the possibilities for product individualisation or the fact that CPQ systems make every product adaptation in the configuration process visible to interested parties as a 3D model.

- The sales department benefits from a faster offer process and a simultaneously higher success rate: The know-how required for the sales process is centrally embedded in the CPQ system and can be permanently used digitally. Moreover, the product configurator also ensures that plausibility and completeness checks reduce the error rate of offers: Only technically feasible product variants can be selected and the prices are calculated correctly. Routine tasks are avoided. Even new sales staff without detailed technical knowledge can sell the products successfully. Among its customers, the CPQ provider camos Software und Beratung GmbH has observed that with a CPQ system, the offer generation is up to eight times faster in practice and at the same time the offer quality and success rate are improved.

- Production can reduce manufacturing costs due to economies of scale and compound effects of standardised product modules. In addition, the design is spared from the large number of feasibility enquiries by the sales department. Designers also receive technically correct and complete specifications. This removes any need for time-consuming follow-up questions for the customer and shortens order processing and delivery times.

Where does your Industry 4.0 process chain begin?

The Industry 4.0 initiative has set in motion the important process of not just viewing information technology and the tasks of digitisation as cost factors, but as a key to the future strategy of companies. In order to achieve the key objectives behind the Industry 4.0 concepts in the best possible way, however, it does not suffice to ensure digitisation, networking and automation in production alone: A comprehensive process chain begins with the customer with his custom requirements and is consistently implemented with an integrated CPQ system.

Whitepaper: Future of B2B Sales

In this free whitepaper you will learn:

1. How purchasing behavior for industrial products is changing.

2. What the key challenges for the digitalisation of B2B sales are.

3. How these challenges can be solved with CPQ.

You will be introduced to the fields of action for the digitalisation of B2B sales:

1. Provide relevant information at the right time.

2. Convince emotionally in a digital environment.

3. Ensure a consistent user experience across all channels.

4. Achieve a competitive advantage with short reaction times.

Industry 4.0 today: A lack of customer focus

Components, products, assembly robots and people are increasingly interlinked and communicate with each other across sites: The German industry is in the middle of its fourth industrial revolution - with the Internet as the central technology driver. According to the PWC study ‘Digital Factories 2020: Shaping the future of manufacturing’ 9 out of 10 industrial companies in Germany already invest in the digital factory. They pursuing three overarching goals: Efficiency and revenue increases and a stronger customer focus.

As far as digitisation, networking and automation in the production and logistics sector are concerned, the German industry is on the right track: Today, one in four machines is already smart and networked in factories. Productivity and flexibility in production especially benefit from these technical measures. Yet these things, alone, do not comprise a customer-centric Industry 4.0, yet: To achieve this, companies must also network with their customers in order to focus on their individual requirements. Only if you know the customer requirements and incorporate them into the production process can you exploit the full potential of flexible and efficient production.

Diversity of variants as a key challenge

Customised production opens up new opportunities for value creation: If you manage to understand your customers’ requirements even better and meet their specific wishes in the optimal way, you open up new sources of revenue. At the moment, 78% of German industrial companies have already recognised that customer-centric individualisation of products is a strategically important issue for their company. However, merely 16 % are able to produce a size 1 batch at the cost of series production. The key challenge is that processes and products must be prepared for the necessary product variety. The variety of products offered on the market leads to an unmanageable complexity in production, inflates business processes and reduces economies of scale. Thus, the objective must be a low internal, technical variance on the production side. On the market side of things, on the other hand, the external, functional variety should be kept as large as necessary in order to meet all individual customer requirements. Only when combined can individualisation become the norm and the customers’ and company’s goals can be equally achieved: Customised products under conditions of series production. In practice, CPQ (Configure Price Quote) systems with modular construction kits make this possible.

Cost-effective individualisation with CPQ and modular construction kits

Individualisation thus also preconditions that marketing and engineering are incorporated both strategically and systematically: In which functions does the customer require variance? How can these functions be mapped in the product so that they can be produced quickly, cost-effectively and flexibly? Can synergetic effects from different areas of use with similar requirements be used? The result of these considerations is a concept for modularisation that divides complex products into standardised, functional modules.

CPQ systems take these modularisation concepts to sales - and to the customer. They enable the configuration of products via modular product building blocks and can map all configuration options based on predefined rules: The modules keep the internal variance within limits from the outset, and the set of rules ensures that the ‘buildability’ of the products is guaranteed. The numerous combination options of individual modules promise a high degree of external variance on the market. At the same time, the variety remains easy to control for the customer via a product configurator: He is guided based on his requirements through the variety of products and in the end arrives at the product that suits him best.

Within a holistic and customer-centred Industry 4.0 concept, the configurator at the interface to potential customers represents the starting point of the digital process chain. It already integrates them in the digital processes as early as the product selection and configuration phase, records their wishes in a digital form for the first time and transfers the requirements to the subsequent processes without system disruptions. Prices and offers with cover letter, calculations and drawings are automatically generated on the basis of the custom configuration with CPQ systems, and the offer data can be used seamlessly to make specifications. The orders are transferred to the ERP system, where parts lists and work plans are prepared, in order to then directly trigger production tailored to the customer requirements.

Reaching customer-centric Industry 4.0 goals with CPQ

By using CPQ systems, the goals of holistic Industry 4.0 projects can be achieved: They assist companies in becoming more efficient, focusing more on their customers’ needs and increasing their revenues. The software builds a digital bridge between interested parties, sales and production - with advantages on all three levels:

- The customer experiences a greater focus on their own requirements and acquires a clear idea of ‘their” product already in the offer phase: For example, through the possibilities for product individualisation or the fact that CPQ systems make every product adaptation in the configuration process visible to interested parties as a 3D model.

- The sales department benefits from a faster offer process and a simultaneously higher success rate: The know-how required for the sales process is centrally embedded in the CPQ system and can be permanently used digitally. Moreover, the product configurator also ensures that plausibility and completeness checks reduce the error rate of offers: Only technically feasible product variants can be selected and the prices are calculated correctly. Routine tasks are avoided. Even new sales staff without detailed technical knowledge can sell the products successfully. Among its customers, the CPQ provider camos Software und Beratung GmbH has observed that with a CPQ system, the offer generation is up to eight times faster in practice and at the same time the offer quality and success rate are improved.

- Production can reduce manufacturing costs due to economies of scale and compound effects of standardised product modules. In addition, the design is spared from the large number of feasibility enquiries by the sales department. Designers also receive technically correct and complete specifications. This removes any need for time-consuming follow-up questions for the customer and shortens order processing and delivery times.

Where does your Industry 4.0 process chain begin?

The Industry 4.0 initiative has set in motion the important process of not just viewing information technology and the tasks of digitisation as cost factors, but as a key to the future strategy of companies. In order to achieve the key objectives behind the Industry 4.0 concepts in the best possible way, however, it does not suffice to ensure digitisation, networking and automation in production alone: A comprehensive process chain begins with the customer with his custom requirements and is consistently implemented with an integrated CPQ system.