Use Case TROX – components transformed into central air handling units

This use case illustrates how TROX is building up a new business area by using a configuration solution. Central air handling units can be put together to meet individual customer requirements without the need to change the system.

(PDF 644 KB)

Project goals

To enable the customised configuration of central air handling units (AHUs) and consequently develop a new business area, TROX needed a configuration solution. Amongst other things, the solution had to be capable of carrying out complex technical calculations.

Results

With the support of the camos CPQ solution, TROX has been offering customised AHUs for some time. Development of the new business area has been outstanding.

About TROX

Breathing fresh air is pretty much taken for granted. Hardly anyone gives it a second thought; even if they find themselves in a hotel kitchen three floors below ground level or in a hermetically sealed operating theatre where it is not even possible to open a window. In contrast, TROX GmbH gives the matter a great deal of thought. Based in Neukirchen-Vluyn on the Lower Rhine, since 1951 the company has been tackling the question of how to channel good quality fresh air into large buildings, ship cabins or tunnel systems. To this end, the company‘s 3,700 plus employees throughout the world develop and sell room ventilation and air conditioning components, equipment and systems. In 2014, with its 30 subsidiaries, 14 production sites and 12 research and development centres, TROX generated sales of EUR 455 million.

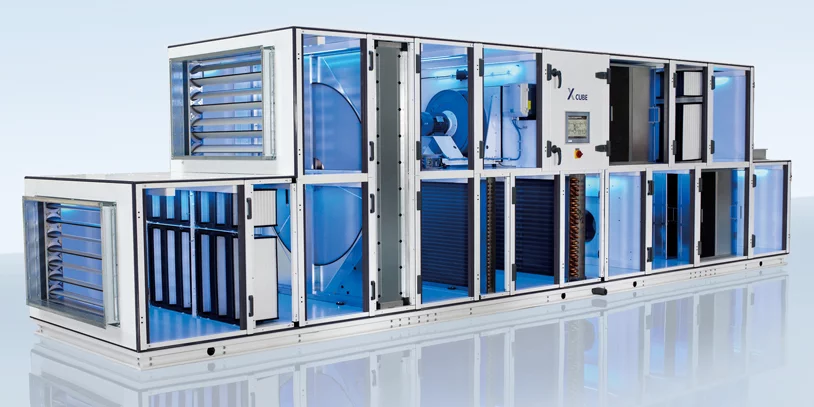

‚Until a few years ago we only manufactured components and functional elements that other providers then built into their air handling units; for example, sound absorbers, filters and louver dampers‘, explained Dirk Gartmann, design system development team leader at TROX. Since 2011, the company has also been manufacturing complete AHUs in-house. These systems comprise a number of technical components that deliver fresh air from outside into the interior and extract the stale air to the outside, thereby filtering out odorous substances, pollutants, particles and dust. Dirk Gartmann: ‚Developing and offering our own air handling units was a logical step for us in terms of the development of the company. We already had most of the high-quality components in our product range. So it was more a matter of configuring these into a complete system‘. The challenge lay in being able to offer each customer – mostly plant constructors – an AHU to fit the building and the scenario in question. Consequently, the systems always had to be individually configured. From the outset it was clear to TROX that the process could not be achieved manually, but required the appropriate software.

The requirements

In essence, Dirk Gartmann and his team could have developed an in-house application. However, as that would have taken too much time, the decision makers opted to use the configuration solution of an external provider. Using the software, the sales engineers needed to be able to precisely document customer requirements, configure suitable air handling units on the basis of these and ultimately generate quotations including comprehensive detailed information and prices. Not an easy task. As adequate ventilation and extraction depends on numerous physical factors, the configurator had to be capable of carrying out complex technical calculations. Achieving these calculations also required a connection to the design systems of manufacturers from whom TROX bought in individual components. Configuration parameter information is transferred to the external solutions in order to then receive proposals for appropriate components including the respective technical data. In addition, specifications can also be called up directly. Having obtained the data, the configurator can ultimately carry out its own calculations and repeat the request where necessary. The new software also needed to be linked to the ERP system. At that time, it was a Baan ERP system, while the solution is now called Infor ERP LN. ‚As such, we knew exactly what we needed and a priority was that our future partner had previous experience in our sector‘, stated Dirk Gartmann.

Selecting the solution

As a TROX employee had already gained positive experience of camos, the Stuttgart-based software and consulting company was invited to a workshop to present a prototype solution. Other providers were also researched over the Internet and their offers assessed. Dirk Gartmann: ‚We quickly opted for camos because their configurator optimally met all our requirements‘.

Inside the project with camos

In the spring of 2011, TROX personnel and camos consultants together began work on adapting the software modules to the individual requirements. ‚camos provided us with tremendous support during this phase, including with the realisation of special concepts. The consultants were always open to our issues and patiently worked with us to find the best option‘, stated Dirk Gartmann. For instance, linking the configurator to the external design system was very challenging from a technical perspective. In each case this was achieved using dynamic link libraries. However, the various systems require the transfer of different parameters depending on the information of relevance for the respective components. Consequently, an individual interface has to be defined for each manufacturer. Following the initial project, in order for this to be achieved without major effort or specific programming knowledge, a standardised process was introduced. This allows new interfaces to be easily integrated and provided with the requisite information. Following complete implementation, the next step was to enter the data on individual AHU components and define the configuration rules. A particular challenge in this respect was mapping the extremely complex mathematical formulas. Ultimately, this was only possible because the development environment of the camos solution not only allowed rules from a previously defined set to be configured via the user interface, but also supported the programming of algorithms and technical or physical calculations.

CPQ solution in use

Sales engineers have been using the configurator for the sale of AHU equipment in the X-CUBE product series since the middle of 2011. The starting point is the precise documentation of customer requirements. For example, the volume in cubic metres to be ventilated and the requisite air quality – air in a kitchen does not need to be as pure as in an operating theatre, but does require greater circulation. The environment in question is also important. Whether a building is situated next to a busy road or on the edge of a wood plays a decisive role, above all in terms of filter selection. Finally, building aspects also need to be documented in order that these can be considered, for example, when calculating the dimensions or weight of the AHU.

Once all the information has been entered, the sales engineer designs an appropriate AHU supported by the configurator, with the design also displayed precisely in graphical format. In this way, possible construction errors are rapidly ascertained and can be rectified. Given the infinite combination possibilities, it may well be the case that, for example, in certain configurations a damper can be awkward to operate. Where TROX employees ascertain such a scenario, the configuration rules are adjusted to avoid the issue in future, consequently increasing the precision of the configurator and constantly improving the AHUs. As a final step, a quotation is generated from the configuration and sent to the prospective customer. Once the quote has been accepted, the X-CUBE configurator transfers the order to the ERP system and forwards the construction data to the CAD solution.

Sales engineers using the configurator on a day-to-day basis were very quickly convinced by the solution. ‚A decisive reason for this is that the camos software covers all the necessary functions and therefore dispenses with the need to switch between systems. This makes work extremely straightforward‘, explained Dirk Gartmann. ‚Nevertheless, our staff are extremely diligent and are constantly finding details that can be improved. Generally such improvements are easily achieved as the camos software is optimally suited for modification and expansion‘. Moreover, the solution is continually being updated with new configuration data and rules. As such, it is constantly being expanded; as is the AHU business, with the configurator contributing significantly to its development.