Use Case Reifenhäuser - efficiency significantly increased

This use case shows you how the family-owned company Reifenhäuser simplified its offer processes and thus significantly increased its efficiency.

(PDF 771 KB)

Project goals

Up to 30,000 components can be combined on a Reifenhäuser extrusion system. Configuration in the past was therefore complex, coordination extensive and the sales process costly. Introduction of a CPQ solution aimed to increase both efficiency and transparency.

Results

Reifenhäuser has been using the camos CPQ solution since 2007. Offer preparation has been carried out markedly quicker since then. One reason is that all the documents are centrally stored and available to all the parties involved. In addition, the knowledge of individual employees has been systematically documented via a set of guidelines. Moreover, Reifenhäuser has successively further developed and augmented the software with a number of useful functions.

About Reifenhäuser

Fresh vegetables – quickly packaged and into the freezer. Thanks to freezer bags, the veg tastes just as good in November, long after the season has ended. Freezer bags are now part of everyday life and we don‘t think twice about them. Yet this nondescript packaging has a fairly complex structure. An inner plastic layer is food-safe and ensures that your asparagus, for example, doesn‘t absorb any extraneous substances; the middle layer ensures that the food in the bag keeps its aroma; and the outer layer can be printed on. These three functional layers are joined together via two bonding layers. A freezer bag consequently has five extremely thin layers that are laminated together. The bags are manufactured and joined together on plastic extrusion systems. Plastic extrusion is where a solid or viscous source material is continuously forced through a form-giving opening under pressure and then further processed.

Reifenhäuser, a family-run company based in Troisdorf, has been building these complex extrusion machines for almost 70 years. Founded as a forge in 1911, the company has since developed into an internationally operating machine and system manufacturer. Reifenhäuser Group currently owns six independently operated subsidiaries with

branches and agencies in 80 countries that generated sales of around EUR 500 million in the 2015/16 business year.

The requirements

Reifenhäuser Cast Sheet Coating – in short CSC – manufactures production systems for cast films, thermoforming films and composites. „Foils play a role in all sorts of areas,“ explained Joachim Bremer, Technical Services Manager at Reifenhäuser. „And they always require very specific features – for example in relation to the source materials being processed, number of laminated layers, thickness and width. The various companies also have diverse requirements as regards the entire manufacturing process. That is why our machines and systems are always individually designed for our customers.

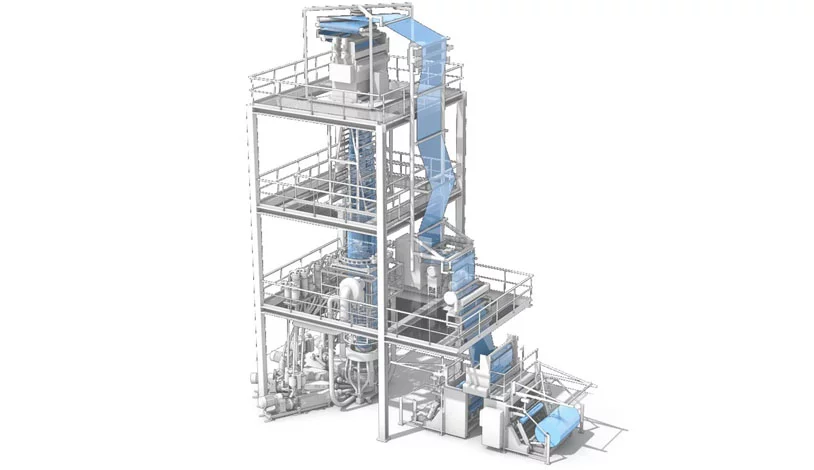

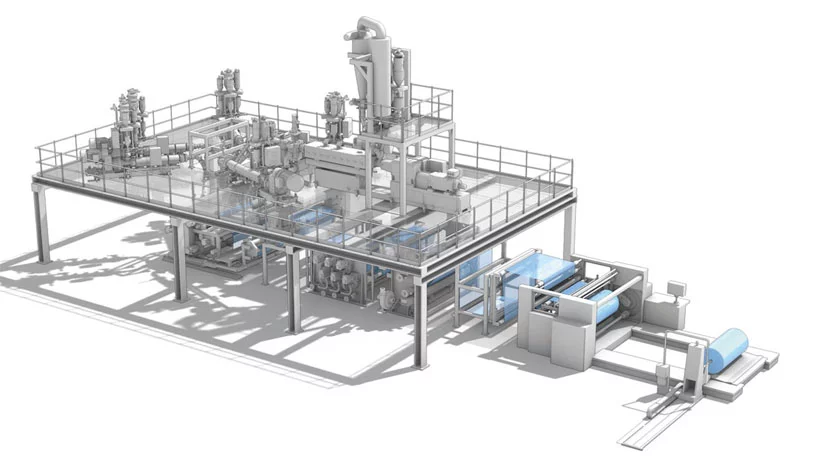

For CSC, that involves the combination of around 3,000 components – from the extruder and flattening device right through to the winding system. In the case of blown film extrusion systems as manufactured by the Reifenhäuser subsidiary Blown Film, this can even involve up to 30,000 components. For many years, sales staff essentially had to know all the characteristic features of the extensive portfolio in its entirety. The only aids available were printed price lists and a file full of text blocks detailing the commensurate components. Once a member of sales had documented the customer‘s requirements, they configured the system – which involved dealing with around 100 items – and calculated the individual price for the offer. The relevant text was then automatically incorporated.

Joachim Bremer: „In most cases, before an offer could be completed the sales department would first have to consult the project management department to clarify the feasibility aspect. The level of coordination required was extremely high, not least due to the fact that storage of the many documents created during the sales process was decentralised. This all meant that the entire process was not as efficient and transparent as it could have been.“ Reifenhäuser also wanted to dispense with the situation where specific knowledge of the system components and configuration lay exclusively with individual employees. Instead, this knowledge was to be managed in a way that made it available to all.

„After implementing an ERP system at our CSC subsidiary, in 2006 we also decided to introduce a CPQ solution in the same area. We wanted to develop systematic guidelines and provide support to sales over the entire offer process,“ explained Joachim Bremer. In addition to a range of functional requirements, for Reifenhäuser it was important that the software featured an object-based development environment so that in-house program customisation could be performed quickly and efficiently. The user interface also had to make it easy for sales staff to configure the systems and create offers.

Selecting the solution

Supported by a consulting agency, those responsible at Reifenhäuser studied the market and looked at six CPQ solutions. Two of the solutions were examined more closely, which included meeting up with the providers. Joachim Bremer: „Both systems largely met our requirements and in our estimation were fairly similar. We ultimately opted for the camos solution because we were thoroughly convinced by the way it allowed us to custom develop.“

Inside the project with camos

After selecting the camos CPQ solution, Reifenhäuser proceeded to adapt and introduce the software, initially using an independent consultant. Implementation was later continued in cooperation with camos. Reifenhäuser employees ascertained the requisite know-how and prepared the texts, with the camos consultants then subsequently incorporating these into the software. ERP and CAD system interfaces were also created. Within six months the CPQ solution was ready for commissioning at Reifenhäuser Cast Sheet Coating.

CPQ solution in use

For ten years now, sales staff have been documenting customer requirements and using the CPQ solution to configure the resulting extrusion systems. First they establish the criteria the system has to fulfil. The software then displays all the possible components and the sales employee simply selects from these. Another supporting feature is that the CPQ solution takes into account all the interdependencies. Only components that are compatible with those already selected are consequently proposed. Sales staff can also identify the items for which components have to be selected. Joachim Bremer: „Another advantage is that during configuration, in addition to showing the standard price, the contribution margin for the entire offer is also displayed. That is important information for sales staff in the course of individual price structuring.“ After concluding the configuration, the offer is then generated automatically on the basis of the data provided. Currently the offer can be generated in seven languages, including Chinese.

Sales staff are supported not only during the configuration phase, but throughout the entire sales process. Via the integrated opportunity management feature, all information from initial contact with a potential customer to order conclusion is documented and stored on a centralised database. Access rights for employees in other departments can be conveniently managed by the responsible sales staff member. „Following introduction of the CPQ solution, efficiency within the entire sales process rapidly increased, as did transparency,“ revealed Bremer. „Moreover, new employees are now very quickly able to provide customers with excellent service as the requisite know-how is readily available within the system.“ To tap the potential of the camos software to the greatest possible extent, over the years Reifenhäuser has expanded the software by a series of functions, including risk assessment and project-based reporting. Joachim Bremer: „We are absolutely delighted with the CPQ solution, which is why our Blown Film subsidiary has also been using the software since March 2017.“