Use Case Haver & Boecker - Significant acceleration of sales processes

In this Use Case you will learn how the family-owned company Haver & Boecker significantly accelerates its sales processes with the CPQ solution.

(PDF 574 KB)

Project goals

From the sales opportunity to configuration and order – Haver & Boecker planned to revamp its entire sales process to increase efficiency and reliability. To this end, the company needed high-performance, state-of-the-art software that was capable of integrating all the various phases and was also easy to use.

Results

Instead of taking two days, quotations can now be generated within three hours. Sales staff use the freed-up time to acquire new customers and consequently increase turnover. In addition, Haver & Boecker uses analyses of the comprehensive sales data to prepare strategic decisions.

About Haver & Boecker

The history of the family-run enterprise Haver & Boecker began more than 125 years ago in Hohenlimburg, near Hagen, Germany. It was here that in 1887 Carl Haver and Eduard Boecker founded a wire weaving company equipped with six mechanical looms to produce premium-quality meshes. In 1913, the company also began producing precision-woven fabric for screen printing and particle analysis became possible with Haver & Boecker products. Gradually, a new area of business developed that saw the company producing machines incorporating its own woven wire cloth.

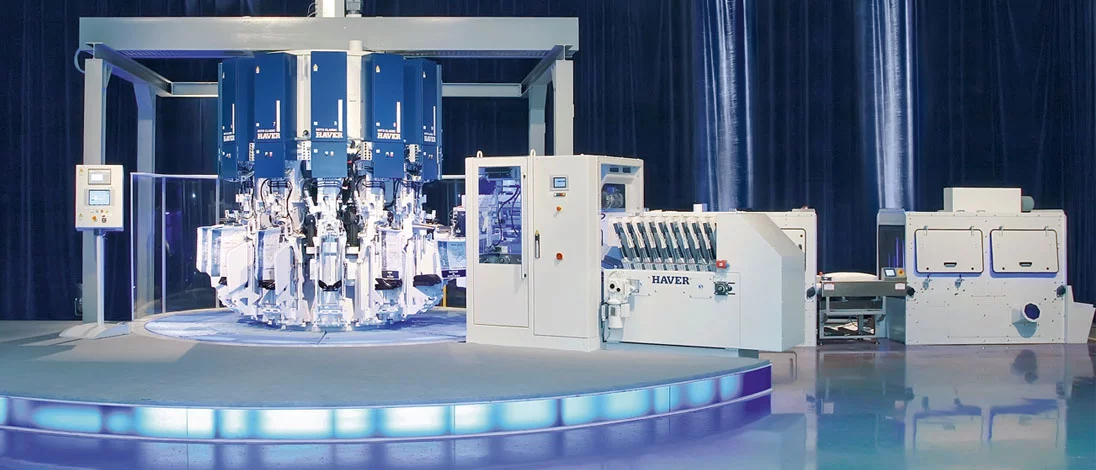

To this day, that formula remains unchanged: Haver & Boecker furnishes its customers with woven wire cloth for use in architecture, industry, screen printing and the hobby sector. The company also specialises in material filling machines andsystems used in the packing and processing of cement, construction materials, minerals, chemicals and foodstuffs.

On this basis, Haver & Boecker has developed into a global player. From Oelde in Westphalia, the company manages 50 subsidiaries and over 150 agencies worldwide, generating sales of around EUR 470 million in 2013.

for material filling.

The requirements

For over 50 years the HAVER ROTO-PACKER® – a rotating machine for packing bulk materials – has been a cornerstone of the product portfolio. ‚The basic function is always identical. However, the packing machine has to be individually configured for each application scenario‘, explained Ann-Kristin Kaltefleiter-Jürgens, Head of Machine Shop Sales Management. For this reason, Haver & Boecker has been using a modular design for a number of years, with customers able to select from numerous components. Variation diversity is extremely broad, which makes the sales process commensurately complex. And not just in the case of the HAVER ROTO-PACKER®.

Machines and systems in the other product families are also always configured according to specific requirements. The sales force, made up of engineers with well-honed technical expertise, had been using software developed in-house for quotation generation since the mid-1990s. However, even with the support of this software, completing a quotation and sending it to the prospective customer could take up to two days for complex enquiries. Moreover, use of the software required comprehensive prior knowledge, which meant it could only be used by a small number of subsidiaries.

Ann-Kristin Kaltefleiter-Jürgens: ‚As a result, at some stage it became clear to colleagues in sales and the management that we needed an efficient, state-of-the-art solution. Our objective was to create not just faster, but also absolutely reliable quotations. We also wanted a solution capable of consistently mapping the entire sales process; from initial contact with a prospective customer through to order confirmation. Our requirements for the IT solution were therefore somewhat stringent‘.

Selecting the solution

To gain an insight, the respective decision-makers first contacted the Mechanical Engineering Industry Association (VDMA) for information on suitable software providers. Four providers were subsequently invited to Oelde to present their solution – one being camos. It was the approach of the Stuttgart-based software and consulting company that struck the right chord.

‚camos was able to map the entire process just as we had envisaged. Additional factors were that quotations could be generated directly from the configurator and standard Office applications could also be incorporated. That means users do not need to constantly switch from system to system. And all this possible via a user-friendly interface,‘ explained Ann-Kristin Kaltefleiter-Jürgens. An added benefit was the certified SAP interface that enables confirmed orders to be forwarded directly to the ERP system. Consequently, camos was commissioned with developing a prototype for the HAVER ROTO-PACKER®, which was duly presented in a workshop at Haver & Boecker to around 40 participating employees from various different specialist departments.

Ann-Kristin Kaltefleiter-Jürgens: ‚It was extremely important to us that colleagues who would subsequently be using the system were able to give their input before the final decision was taken. Only after receiving a positive response from these colleagues did we award the project to camos‘.

Inside the project with camos

From the kick-off in autumn 2010, Haver & Boecker staff worked closely with the camos consultants. Together they adapted the individual software modules to the specific requirements and programmed the requisite interfaces. The major part of the work involved the systematisation of machine configuration data and definition of the configuration rules. Following various tests, the project was ready in spring 2012 and the first quotation was able to be generated with the aid of the new system.

CPQ solution in use

The sales process has changed significantly for the sales force. Immediately upon being contacted by a company with an enquiry, a sales representative will work with the customer contact to decide which technology offers the best solution for the project. A sales enquiry – and consequently a sales opportunity – is then entered into the new system.

All documents generated within the ongoing process, such as emails, Word and Excel documents, specifications, technical drawings and the quotation itself, are allocated to the project and systematically logged. Potential customer requirements and specific parameters are also documented, for example, operating hours or technical data relating to existing systems. Applying this information, the sales representative uses the configurator to create the appropriate machine or system. Once all components have been selected, the system automatically generates the quotation including all prices and texts detailing the individual components. Instead of taking two days as previously, the process can now be completed in just three hours.

As such, with the help of camos, Haver & Boecker has now achieved its objective of generating quotations significantly faster and without error. Sales staff are now able to use the freed-up time to acquire new customers. ‚We‘ve clearly noticed that our sales colleagues are out and about much more and the number of quotations has appreciably increased,‘ stated Ann-Kristin Kaltefleiter-Jürgens.

In addition, the new system also supports the sales team in terms of managing customer relations. For example, alerts automatically send a reminder to actively follow up on a prospect that has not been in contact for a certain period of time. Upon sending the second version of the quote they are also obliged to estimate and document the likelihood and date of an order.

As a result, comprehensive data is now available that can be consolidated into statements via various reporting functions and used for strategic alignment of both sales and the company. Ann-Kristin Kaltefleiter-Jürgens: ‚At the start of the project we hadn‘t even considered these possibilities. We now greatly appreciate these benefits‘. Despite this, for Haver & Boecker the process is far from complete. In mid-2014 the system was introduced at a subsidiary in the USA, followed by a subsidiary in France at the start of 2015. Roll-out at a company in Münster is also currently in the pipeline.