Use Case B&R – set for further global expansion

This use case shows you how the worldwide automation specialist B&R uses CPQ to optimize its offer processes at all locations more efficiently and with a high quality standard.

(PDF 435 KB)

Project goals

In order to keep pace with its rapid global growth, B&R needed a CPQ (Configure Price Quote) solution capable of supporting the sales force with quotation generation in all the various countries. In addition, the entire process needed to be accelerated and run without a hitch.

Results

The CPQ solution was rolled out at all the various company locations. Consequently, quotation generation now takes less than an hour. Sales staff save time and are simultaneously supported by the product configurator, thereby avoiding errors in terms of the products offered.

About B&R

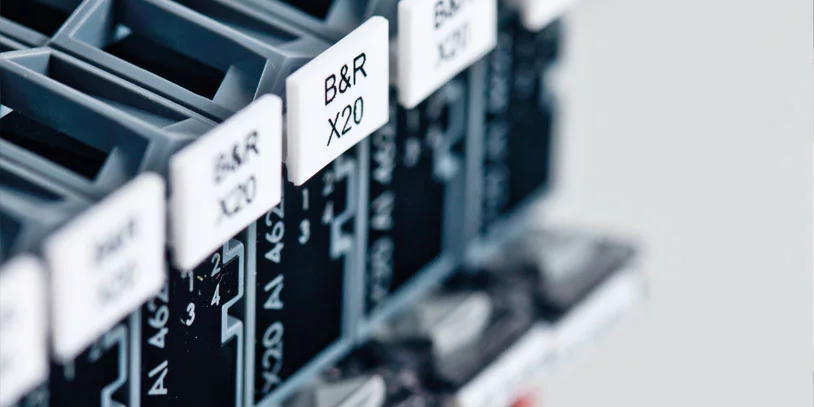

When Josef Raschhofer is approached on the subject of Industry 4.0, he responds with self-assurance: ‚It‘s good that there is finally a term to describe what we have been doing for years in some areas‘. Raschhofer is head of IT and supply chain management at B&R. Since its foundation in 1979, the Austrian company has been involved in the automation of machinery and systems. The product portfolio includes industrial PCs, motion control and control systems. Control technology, software and services are also offered. Most of these products are an essential requirement where machines and systems are networked within a smart factory in order to facilitate autonomous control – one of the crucial aspects of Industry 4.0. B&R currently employs around 2,800 employees and is represented through over 180 offices worldwide. As previously, the company continues to grow rapidly and is expanding across the globe. Primary customers of B&R are engineering companies that integrate the PCs, motion controls and control facilities within their systems. Given that the respective requirements are generally highly specific, B&R has developed many of its products on a modular basis. One example being the X20 control system. With the X20 customers can select from over 500 modules – including bus modules and CPUs, input and output modules as well as network and measurement modules – and numerous different versions to configure just the right system. ‚Achieving a broad variety with a modular system is absolutely imperative from a technical and logistical perspective,‘ stated Josef Raschhofer.

The requirements

For around 20 years B&R has been supporting configuration and quotation generation with IT solutions. Initially, rules were logged in the SAP system and a quotation tool developed on the basis of Lotus Notes, which was supplied via an interface with SAP master data. Then came the application of Excel to calculate and Word to create the quotation document. From 2008, customers ultimately had the option of configuring the desired products themselves using a web configurator. Developed in this way, the heterogeneous landscape made it extremely difficult to maintain the overview. For experienced sales staff this was not a problem. However, support was frequently required for more complex quotes, above all for younger colleagues and new employees in the international branches. All of which added to the average cost of quotation generation. At the same time, errors were rife on account of the system not operating seamlessly and the non-standardised database. Configured products could not be produced in some circumstances or offers were incomplete. Josef Raschhofer: ‚We were also dissatisfied with the fact that there was no standard layout for quotations. For all these reasons, we decided to introduce a new configuration solution‘. The aim of the solution was to ensure that comprehensive product and standard know-how was systematically documented and available for all employees at all the various locations. Any new colleagues should then also be in a position to quickly and independently generate accurate quotations after just a short period of time with the company. In terms of the further expansion of B&R, this was a central prerequisite of major strategic importance.

Selecting the solution

In their search for suitable CPQ software, it wasn‘t long before those responsible came across camos. ‚We already knew the name at the start of our market research. Even after the very first discussions we were confident that the camos consultants understood precisely what we were looking for. It was not just a question of the technical aspects of the software. Above all, we were impressed by an obvious understanding of the processes – from acceptance of the customer requirements through to transfer of the order to SAP.“

Inside the project with camos

Once the project began in mid-2012, B&R employees from the relevant specialist departments and IT got together with camos to define in detail the functions required of the new configuration solution. The software was then subsequently implemented, embedded in the existing CRM solution and linked to SAP ERP, the editing system and the email program that sends out the quotes. The product and standard know-how required for configuration was incorporated in the final step. ‚We paid close attention to the perceptions of sales staff‘, explained Josef Raschhofer. By the second half of 2013 we were already able to locate individual modules or components within the overall offer with accuracy using the solution. January 2014 saw the roll out of the new solution.

CPQ solution in use

The solution has since been introduced at all B&R locations throughout the world, enabling quotations to be created in a total of 19 languages – including Korean, Chinese and Japanese, for example.

Today, sales personnel in all the various countries enter a new prospective sale into the CRM system, from where they can directly initiate the quotation and configuration solution. Following technical configuration and commercial calculation based on the prices and terms for the customer currently logged within the SAP system, the quotation document is generated at the push of a button. The document is primarily prepared using text modules that are drawn from a central editing system and which, as an example, highlight the USP of a product. Various graphical elements can also be added. Depending on the level of authorisation, users can include discounts within the quotation or amend other terms. The quotation can be sent from the tool directly by email and is automatically documented as a pdf file in the CRM system. Upon acceptance of a quote by the customer, new configuration data – for example, for an industrial PC – can be transferred to SAP ERP by a simple click, whereupon the requisite master data needed to process the order and for production, individual stock lists and work schedules are automatically generated.

In this way, B&R sales personnel are able to create error-free quotations significantly more quickly. Moreover, already clearly apparent is the fact that the solution can be easily and cost-effectively introduced at new locations and local staff are quickly able to work with it. ‚That is extremely important for us. Our sales staff are optimally supported by the CPQ solution in their day-to-day tasks‘, explained Josef Raschhofer. ‚This also benefits our customers to whom our sales force are able to devote sufficient time to finding just the right automation solution for each machine‘. The fact that all quotations are now stored centrally also facilitates systematic analysis. As such, in future B&R will be able to determine which products customers prefer and for what reason, in order to then develop more targeted innovations. In this respect, Industry 4.0 and networking within the smart factory will most certainly play a decisive role.