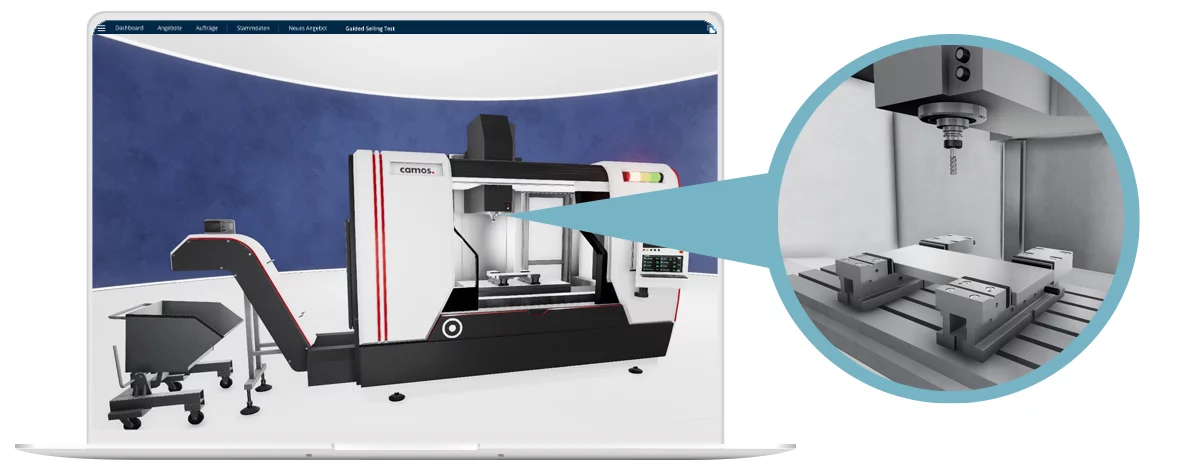

camos & CMC Engineers combine product configuration with 3D visualisation

Stuttgart, 18 May 2022 - The CPQ specialist camos Software und Beratung GmbH and CMC Engineers GmbH, which specialises in the visualisation of technical products, are bundling their competences in a strategic partnership. Together, they enable producers of complex and multi-variant products a competitive edge by using photorealistic 3D visualization based on Unity 3D's market-leading visualization technology. Closely integrated with the product configuration, it is already used in an early phase of the quotation process.

Adding a 3D visualisation to the product configuration in the quotation process brings decisive and revenue-increasing advantages. It is obvious that a 3D visualisation optimally demonstrates the configured product and makes complex interrelationships comprehensible. Customers experience how their product is virtually created and how their decisions affect the configuration. A faulty selection in the configuration process immediately catches the eye and can be corrected. Manufacturers can perfectly showcase the unique selling points of their products visually. They bring products to market faster because they can already be presented virtually before the physical counterpart has been built. The product presentation on the manufacturer's website is also fundamentally improved. Through 3D visualisation, customers are reached on an emotional and involving level even without personal contact. With a guided selling process, the CPQ system ensures that online users can configure products in a self-service procedure, obtain quotations and also complete the purchase via a check-out functionality. The configuration logics stored in the CPQ ensure that only products that are technically feasible can be configured.

Existing 3D CAD data can serve as the basis for the visualisation. In order to make this data usable for visual and interactive product configuration, it is visually prepared and linked to the configuration logic. For this purpose, the 3D design data are enriched with appropriate materials and lighting scenarios and optimised for real-time display. As a result, the detailed 3D model can be rotated and enlarged as desired. The camera perspective adjusts automatically. For example, the interior of a machine is focused when changes are made to the interior of the machine via the product configuration. Conversely, the user can navigate to the appropriate position in the configuration using the 3D model. Elements can also be moved, added or changed directly in the visual 3D model using drag and drop. The configuration adapts accordingly.

The customers of CMC Engineers GmbH and camos Software und Beratung GmbH will benefit from these new capabilities in the future. CMC Engineers specialises in technical visualisations in the field of mechanical and plant engineering and relies on the market-leading visualisation technology of Unity 3D. camos develops one of the leading CPQ solutions for quotation generation and product configuration in the B2B market. By bundling the visualisation and configuration competences of both companies, a solution can be offered that is adapted to the requirements of technically complex B2B products.

Simon Märkle, Managing Director at camos: "We are convinced that the customers of both companies will benefit from these bundled competences and a holistic solution offering from a 3D visualisation integrated into the CPQ quotation process. With this combination, our customers' sales will present their products even more attractively and convincingly. Especially in a time when an outstanding customer experience can be decisive for the purchase decision, this is important."

Julian Hermle, Managing Director of CMC Engineers: "We firmly believe in the emotional impact of product visualisations and are very pleased to have found a partner in the CPQ environment with the same mindset. With our know-how in real-time visualisation and the market and technology leadership of camos, we form a powerful team for the implementation of product configurators that will shape the future".